| |

| |

| |

| |

| |

| |

| |

qualitative and quantitative analysis of crystalline compounds. The

technique provides information that cannot be obtained any other way. The

information obtained includes types and nature of crystalline phases

present, structural make-up of phases, degree of crystallinity, amount of

amorphous content, microstrain & size and orientation of crystallites.

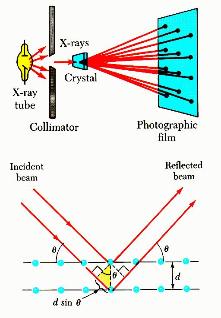

monochromatic X-rays, the atomic lattice of the sample acts as a three

dimensional diffraction grating causing the X-ray beam to be diffracted to

specific angles. The diffraction pattern, that includes position (angles) and

intensities of the diffracted beam, provides several information about the

sample and are discussed below:

- Angles are used to calculate the interplanar atomic spacings (d-

spacings). Because every crystalline material will give a characteristic

diffraction pattern and can act as a unique ‘fingerprint’, the position (d)

and intensity (I) information are used to identify the type of material by

comparing them with patterns for over 80,000 data entries in the

International Powder Diffraction File (PDF) database, complied by the

Joint Committee for Powder Diffraction Standards (JCPDS). By this

method, identification of any crystalline compounds, even in a complex

sample, can be made. - The position (d) of diffracted peaks also provides information about

how the atoms are arranged within the crystalline compound (unit cell

size or lattice parameter). The intensity information is used to assess

the type and nature of atoms. Determination of lattice parameter helps

understand extent of solid solution (complete or partial substitution of

one element for another, as in some alloys) in a sample. - Width of the diffracted peaks is used to determine crystallite size and

micro-strain in the sample. - The ‘d’ and ‘I’ from a phase can also be used to quantitatively estimate

the amount of that phase in a multi-component mixture.

No problem is too big.

We are the experts in

materials testing and failure

analysis.

(800) 682 - 2922

but also for quantitative estimation of various crystalline phases. This is one

of the important advantage of X-ray diffraction technique. Several methods

have been proposed and successfully used to quantify crystalline phases in

mixtures. They include external standard methods, the

reference-intensity-ratio (RIR) method, chemical methods and the whole

pattern fitting Rietveld method. Of the available methods, the Rietveld

method is probably the most accurate and reliable method. The Rietveld

method is a whole-pattern fitting least squares refinement technique and

has been successfully used for quantification and characterization of

inorganic and organic compounds It has also been used for crystal structure

refinement, to determine size and strain of crystallites.